Understanding Panels in Industrial Automation

Panels serve as the central hub for housing and organizing electrical components, control devices, and automation equipment in industrial automation systems. In this comprehensive guide, we explore the significance of panels, their types, functions, design considerations, and applications across diverse industrial settings.

Introduction to Panels:

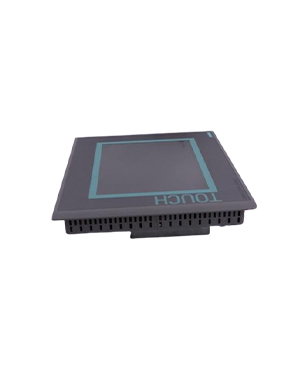

Panels, also known as control panels or electrical panels, are enclosures designed to house and protect electrical and electronic components used in industrial automation. These components may include power supplies, circuit breakers, contactors, relays, PLCs, HMIs, drives, and various sensors and actuators. Panels provide a centralized location for connecting and organizing these components, facilitating easy installation, maintenance, and troubleshooting of automation systems.

Types of Panels:

- Control Panels: Control panels house components related to the control and monitoring of industrial processes, such as PLCs, HMIs, drives, and control devices. These panels often include operator interfaces for interacting with the automation system.

- Power Distribution Panels: Power distribution panels distribute electrical power from the main supply to various components and equipment within the automation system. These panels typically include circuit breakers, fuses, contactors, and other protective devices to ensure safe and reliable power distribution.

- Motor Control Centers (MCCs): MCCs are specialized panels used to control and protect electric motors in industrial applications. They contain motor starters, overload relays, and other motor control devices, allowing for centralized control and monitoring of motor-driven equipment.

- Instrumentation Panels: Instrumentation panels house instruments and sensors used to measure and monitor process variables such as temperature, pressure, flow, and level. These panels often include displays, indicators, and transmitters for transmitting data to control systems.

Functions of Panels:

Panels perform several key functions within industrial automation systems:

- Protection: Panels provide protection for electrical components and equipment against environmental factors such as dust, moisture, temperature extremes, and physical damage, ensuring reliable operation in harsh industrial environments.

- Organization: Panels organize electrical wiring, cables, and components in a structured manner, minimizing clutter and simplifying installation, maintenance, and troubleshooting of automation systems.

- Distribution: Panels distribute electrical power from the main supply to various components and equipment within the automation system, ensuring efficient and reliable power distribution.

- Control and Monitoring: Panels facilitate control and monitoring of industrial processes by housing control devices, instrumentation, and operator interfaces, allowing operators to interact with and supervise the automation system.

Design Considerations:

When designing panels for industrial automation, several factors must be considered to ensure optimal performance and reliability:

- Environmental Conditions: Panels should be designed to withstand the environmental conditions present in the industrial environment, including temperature variations, humidity, dust, and vibration.

- Space Constraints: Panels should be sized appropriately to accommodate all required components while considering space constraints and accessibility for installation, maintenance, and future expansion.

- Safety: Panels should incorporate safety features such as circuit protection devices, emergency stops, and warning labels to prevent electrical hazards and ensure the safety of personnel working with the automation system.

- Accessibility: Panels should be designed for easy access to components and wiring for maintenance and troubleshooting purposes, with clear labeling and documentation to aid technicians.

Applications of Panels:

Panels find applications across a wide range of industries and processes, including:

- Manufacturing: In manufacturing plants, panels control and monitor processes such as assembly lines, packaging, material handling, and quality inspection, ensuring efficient production and product quality.

- Utilities: In utilities such as power generation, water treatment, and HVAC systems, panels control and monitor equipment such as pumps, motors, turbines, and compressors, optimizing performance and reliability.

- Infrastructure: In infrastructure applications such as transportation systems, buildings, and facilities, panels control and monitor systems such as lighting, ventilation, access control, and security, enhancing safety, comfort, and efficiency.

- Renewable Energy: In renewable energy systems such as solar farms and wind turbines, panels house control and monitoring equipment for optimizing energy production and grid integration.